Why a Clean Block is the Foundation of a Great Engine

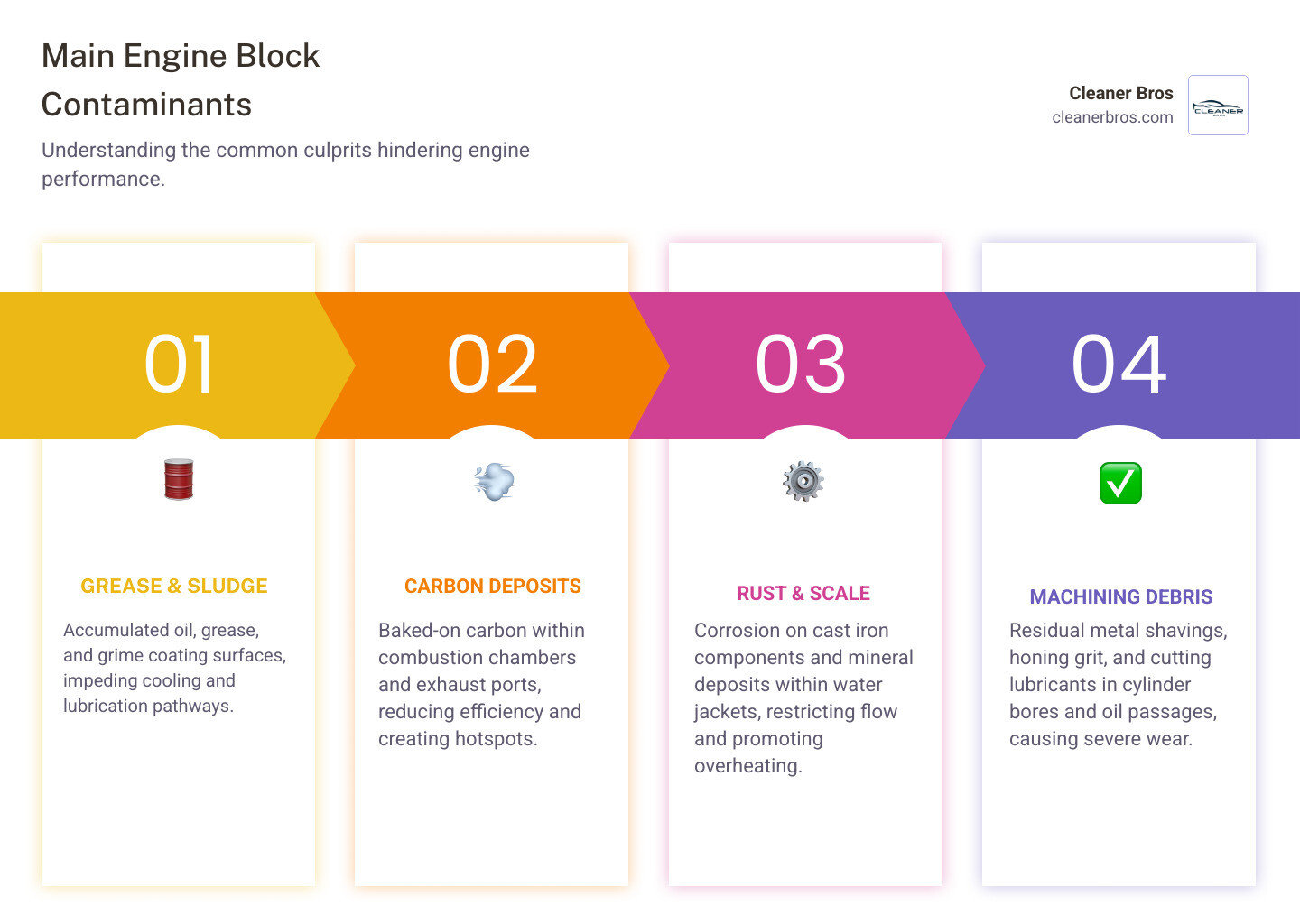

Chemical cleaning engine block is the process of using specialized cleaners to remove years of accumulated grease, oil, carbon deposits, rust, and machining debris from an engine block before rebuilding or reassembly.

Quick Answer: How to Chemically Clean an Engine Block

- Strip and degrease using automotive degreasers, kerosene, or diesel fuel

- Remove rust with mild acids like vinegar or phosphoric acid-based cleaners

- Match your method to your material – cast iron tolerates caustic cleaners, aluminum requires pH-neutral solutions

- Final wash after machining with hot soapy water and brushes to remove metal shavings

- Dry completely with compressed air to prevent flash rust

If you’ve pulled an engine apart for a rebuild, you know the sight: a block caked with sludge and rust. Building on a dirty foundation is a recipe for failure. Metal chips left in oil passages can destroy bearings, and honing residue can damage new rings. Proper cleaning isn’t optional—it’s the foundation of a successful rebuild.

While professional hot tank cleaning can cost $200 or more, you can achieve professional-level results at home with the right chemicals, safety gear, and some elbow grease. This guide will show you how to tackle chemical cleaning for both cast iron and aluminum blocks.

Safety First: Prepping Your Workspace and Yourself

Skipping safety prep for chemical cleaning engine block parts can lead to injury or environmental damage. The chemicals used are powerful and can harm your skin, lungs, and eyes.

Start with your workspace. Ensure serious ventilation by using fans to pull fumes out of your garage or by working outside, upwind of your project. Solvents and degreasers release Volatile Organic Compounds (VOCs) that are hazardous with prolonged exposure.

Proper drainage is essential. Never let chemical-laden runoff flow into a storm drain. Use a large containment tarp to catch contaminated water. If you have a shop drain, confirm it connects to a proper waste system.

Now for the most important part: protecting yourself.

- Chemical-resistant gloves: Use heavy-duty nitrile or neoprene gloves. Regular latex gloves will dissolve.

- Safety glasses or goggles: They must seal around your eyes to protect from splashes. A single drop of caustic cleaner can cause permanent damage.

- A proper respirator: A paper dust mask is not enough. Use a respirator rated for chemical vapors and organic compounds.

Before you start, read the Material Safety Data Sheet (MSDS) for every chemical. It provides crucial safety and handling information. Never mix different cleaners unless instructed, as this can create toxic gases. Always add chemicals to water, not the other way around, to prevent violent reactions. Plan for responsible waste disposal by contacting your local hazardous waste facility about used solvents and contaminated water.

A Guide to Chemical Cleaning an Engine Block at Home

You can achieve professional-grade chemical cleaning engine block results at home with a smart soaking strategy. The secret is patience: giving chemicals time to work in a large plastic tub or drum will loosen and dissolve decades of gunk.

Choose between traditional solvents and modern aqueous (water-based) solutions. While solvents are common, aqueous cleaners are gaining ground as they are non-flammable, produce fewer VOCs, and are safer to handle. At Cleaner Bros, we champion eco-friendly solutions, and you can learn more about our Eco-Friendly Car Cleaning approach.

Soaking is effective at reaching tiny oil passages and hidden crevices, but it won’t do everything. You’ll still need to do some manual scrubbing with stiff brushes, wire brushes (on cast iron only), and long-handled brushes for internal passages.

Removing Grease, Oil, and Sludge

First, tackle the thick layer of grease, oil, and sludge. Start by using scraping tools to remove the thickest chunks. Next, apply an automotive-specific engine degreaser, let it sit as directed, and agitate with a stiff brush.

For a budget-friendly option, kerosene and diesel fuel are effective at dissolving heavy grease. Many DIYers soak parts in a tub of diesel fuel, which you can read about in forum discussions. These are flammable and have strong fumes, so prioritize ventilation and safety. After degreasing, a pressure washer can remove loosened grime, but use caution to avoid damaging sensitive surfaces.

How to Effectively Remove Rust and Corrosion

For cast iron blocks, rust is a common problem. Mild acids are effective for light to moderate rust. A white vinegar soak works well, as do commercial rust dissolvers with citric or phosphoric acid.

After removing rust, you must prevent flash rust, which forms instantly when bare metal is exposed to water and air. To prevent it, rinse thoroughly and then immediately dry every surface with compressed air. After drying, apply a water-displacing aerosol or corrosion inhibitor to create a protective barrier.

Cleaning Aluminum vs. Cast Iron Blocks: What You Must Know

The material of your engine block dictates your cleaning method. What works for cast iron can destroy aluminum.

Cast iron is tough. It handles aggressive caustic cleaners and high temperatures (180°F+ in hot tanks, 650-750°F in thermal ovens).

Aluminum is sensitive. It’s softer and more reactive. Caustic cleaners will etch or damage it; you must use pH-neutral or aluminum-safe cleaners. High temperatures are also a risk: aluminum can anneal (soften) if exposed to 500°F or more.

Abrasive blasting also differs. Cast iron can handle glass beads, while aluminum requires softer media like baking soda at lower pressures.

Here’s a quick comparison to keep you on track:

| Feature | Cast Iron Blocks | Aluminum Blocks |

|---|---|---|

| Cleaning Agents | Caustic (high pH) solutions, strong degreasers | pH-neutral or aluminum-safe cleaners, mild degreasers |

| Temperatures | High heat (180°F+ for chemical, 650-750°F for thermal) | Moderate heat (avoid above 500°F for extended periods) |

| Abrasive Blasting | Glass beads, aluminum oxide, steel shot (watch for media retention) | Baking soda, plastic media, glass beads (lower pressure) |

| Rust Removal | Mild acids (vinegar, phosphoric), rust dissolvers | Not typically a rust issue, focus on oxidation removal |

| Key Risk | Flash rust after water-based cleaning | Etching, annealing, discoloration, structural damage |

Always check product labels for material compatibility and test on an inconspicuous area first.

The All-Important Final Wash: After Machining, Before Assembly

After machining, your engine block looks clean, but it’s not ready for assembly. The final wash is a critical step. Machining creates invisible enemies: machining debris, metal shavings, cutting lubricants, and honing residue. If not removed, these contaminants will circulate and destroy your new engine by scoring bearings and cylinder walls.

Modern engines have precision tolerances that require a sterile assembly environment. Every oil galley, bolt hole, and surface must be spotless. This final wash also ensures proper adhesion for paint or coatings.

While we’re talking about keeping things clean, maintaining your engine bay between rebuilds is just as important. For routine maintenance, check out our professional Engine Bay Detail service. We also offer a comprehensive range of detailing add-ons to keep your entire vehicle in top shape.

How to Clean an Engine Block After Machining

This methodical process requires your full attention.

- Immerse in hot soapy water. Use the hottest water possible with a strong degreasing laundry detergent.

- Scrub cylinder bores. Honing residue must be scrubbed with a stiff cylinder brush and hot soapy water until the brush comes out clean.

- Clean oil passages. Use rifle cleaning kits and small brushes to scrub every oil galley. Flush repeatedly with hot soapy water until clear water runs through.

- Rinse thoroughly. Flush the entire block with copious amounts of clean, hot water to remove all soap and contaminants.

- Dry immediately and completely. Use an air compressor to blow water from every surface. This prevents flash rust on cast iron. The block must be bone dry.

Common Mistakes to Avoid in the Cleaning Process

Avoid these common mistakes to ensure a successful rebuild:

- Using the wrong chemicals on aluminum: Caustic cleaners for cast iron will destroy aluminum. Always verify chemical compatibility.

- Inadequate rinsing: Leftover residue can cause corrosion and prevent paint adhesion. Rinse until the water runs perfectly clear.

- Not drying completely: Any moisture on cast iron will cause flash rust. Use compressed air to dry every crevice.

- Ignoring oil galleys: Contaminants hidden in small passages will circulate and cause catastrophic engine damage. Be meticulous.

- Cross-contamination of cleaning media: Abrasive media like glass beads must be completely removed, as trapped particles can destroy the oil pump and bearings.

The final wash is tedious but crucial. Taking your time here is the difference between a long-lasting engine and a quick failure.

Frequently Asked Questions about Engine Block Cleaning

You’re not alone if you have questions about chemical cleaning engine block components. Let’s explore the most common ones.

What are the best chemicals for chemical cleaning an engine block?

The “best” chemical depends on the contaminant and your block’s material.

- For grease and oil: Use strong alkaline degreasers for cast iron and pH-neutral degreasers for aluminum.

- For carbon deposits: Strong alkaline cleaners work on cast iron, often combined with scrubbing. For aluminum, gentle media blasting with baking soda is a safer option.

- For rust (on cast iron): Mild acids like white vinegar or commercial phosphoric acid-based removers are effective. Use a corrosion inhibitor after rinsing to prevent flash rust.

You can find a discussion on various cleaning chemicals where builders share their experiences. Always read the MSDS before using any chemical.

Can I use household cleaners like oven cleaner on my engine block?

We strongly advise against using household oven cleaner, especially on aluminum. Oven cleaner is extremely caustic and can easily etch, discolor, or corrode aluminum. Its thick consistency also makes it difficult to rinse completely, leading to residue that can cause flash rust on cast iron.

Automotive-specific products are formulated for engine components and are a much safer choice. The small savings aren’t worth the risk of damaging your engine block.

How do professional methods like ultrasonic cleaning work?

Professional shops often use ultrasonic cleaning, which uses high-frequency sound waves to create and collapse millions of microscopic bubbles in a cleaning solution. This process, called cavitation, creates a powerful micro-scrubbing action that cleans every surface, including intricate passages that brushes can’t reach.

A typical cycle involves submerging the block for about 45 minutes at around 75°C. You can learn about the ultrasonic cleaning process in more detail. While not practical for most DIY garages, it highlights the importance of the meticulous final wash.

Conclusion: The Payoff of a Perfectly Clean Engine

Completing the chemical cleaning engine block process is a significant investment of time and effort, but the payoff is a perfect foundation for a successful rebuild. A pristine block leads to improved performance and increased engine longevity. With clean oil passages and no abrasive debris, your engine will run cooler, smoother, and last longer.

We’ve covered everything from safety and chemical selection to the critical final wash. The importance of a clean foundation for any engine build cannot be overstated.

If a full engine rebuild isn’t on your to-do list, but you still want a pristine engine bay, Cleaner Bros can help. Our team specializes in professional mobile detailing, bringing our services to you in Orem, Spanish Fork, Provo, and throughout northern Utah County.

For routine maintenance, our mobile detailing service is the perfect solution. We’ll degrease and detail your engine bay with eco-friendly products for a showroom look without the hassle.

Ready to give your vehicle the care it deserves? Book your professional Engine Bay Detail with Cleaner Bros today, and let us handle the cleaning while you enjoy the results.